Products

- Printing ink for High Density series-Hand printing

- Printing ink for High Density series-Machine printing

- Printing ink for machine printing series

- Water-based printing ink

- Printing Material Auxiliaries series

- Printing ink for hand printing

- Dipping material for rope end webbing

Service hotline:

13827210351

current location:Home>>Products > Printing ink for High Density series-Machine printing > text

PU005A/C Imitation Silicone HD printing ink for Machine printing

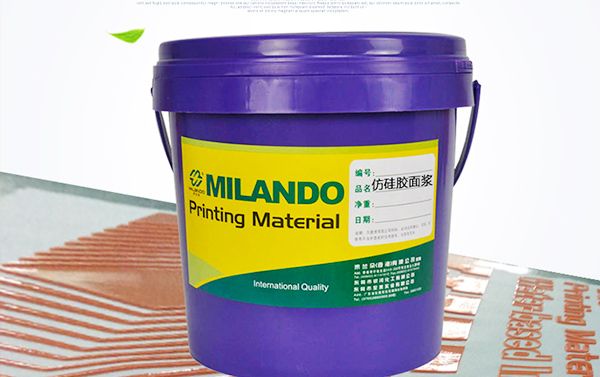

Product Name: PU005A/C Imitation Silicone HD printing ink for Machine printing

Brand: MILANDO

Function: HD printing ink for machine printing

Special service: free sample sending

Packing net weight: 5kg

Shelf life: 6 months

By solvent type: water based paint

PU005A/C Imitation Silicone HD printing ink for Machine printing

Content introduction

1、Performance

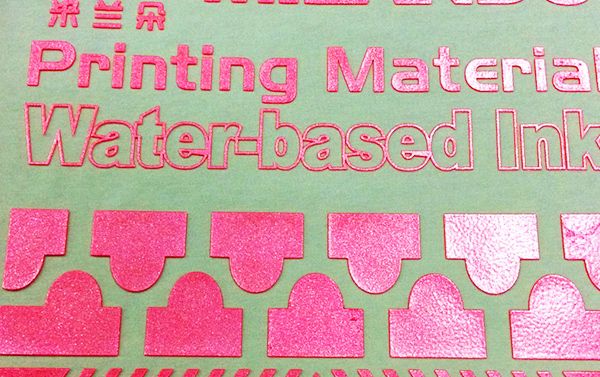

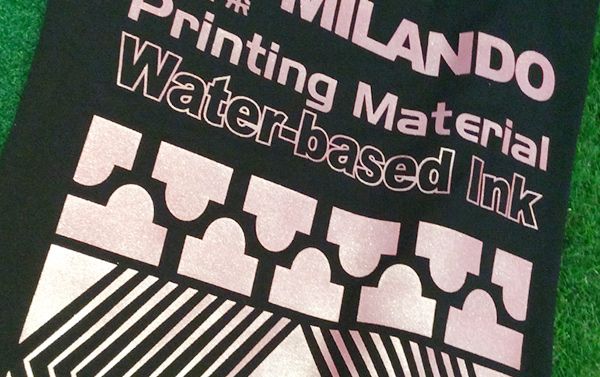

Appearance: pu005 is slightly micro yellow, pu005a is pure white

Features: good hand feel, antiskid, high transparency, general thickness, tensile force, good resilience, dry surface, cold resistance - 10 degrees. It is recommended to overheat the printed side after drying.

1. Viscosity: 12500 ~ 13000cps;

2. Ionic: non-ionic;

3. Storage period: 6 months (normal temperature, sealed).

2、 Application: apply

1. The product is mainly used for three-dimensional thick plate printing of nylon cloth, knitted cotton cloth, insole, middle end gloves, high-grade crafts, etc;

2. This product generally uses 80 mesh 120 mesh screen, according to the different patterns of the screen must be tight, this is quite key;

3. The product is not easy to plug the net. When it is too thick, it can be evenly diluted by adding a proper amount of water slurry;

4. In order to ensure the printing effect, it is generally required to print 8-10 times according to different thickness;

5. This product is easy to operate. It is generally recommended to directly use flat screen (ordinary screen) without making thick plate. When printing with thick plate screen, the second printing shall be carried out after the first printing is completely dry;

6. 2% mld-888 additive must be added when using;

7. After natural drying for 24-48 hours or drying at 60 ℃ - 80 ℃ for 45 minutes, the reverse side of the fabric shall be overheated for 135 ℃ - 140 ℃ for 1-2 minutes (the specific temperature can be adjusted appropriately according to the temperature resistance of the fabric);

8. Suitable for: hand printing, elliptical printing machine printing.