Products

- Printing ink for High Density series-Hand printing

- Printing ink for High Density series-Machine printing

- Printing ink for machine printing series

- Water-based printing ink

- Printing Material Auxiliaries series

- Printing ink for hand printing

- Dipping material for rope end webbing

Service hotline:

13827210351

current location:Home>>Products > Printing ink for High Density series-Machine printing > text

H-105FM-5/AM-5 Thick plus High density printing ink

Product Name:H-105FM-5/AM-5 Thick plus High density printing ink

Brand: MILANDO

Function: HD printing ink for machine printing

Special service: free sample

Packing net weight: 5kg

Shelf life: 6 months

By solvent type: water based paint

H-105FM-5/AM-5 Thick plus High density printing ink

Content introduction

Introduction

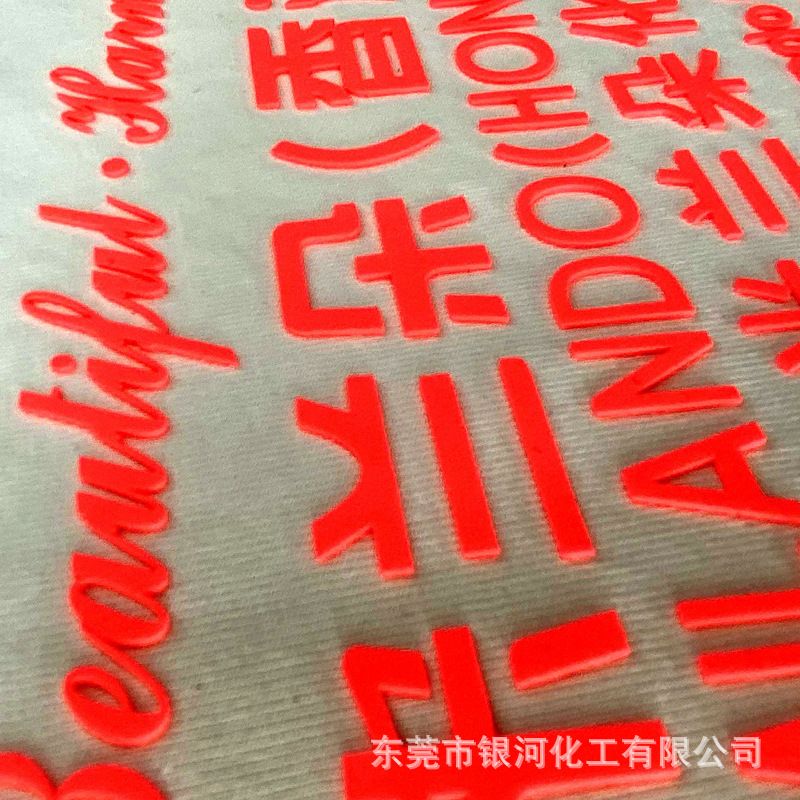

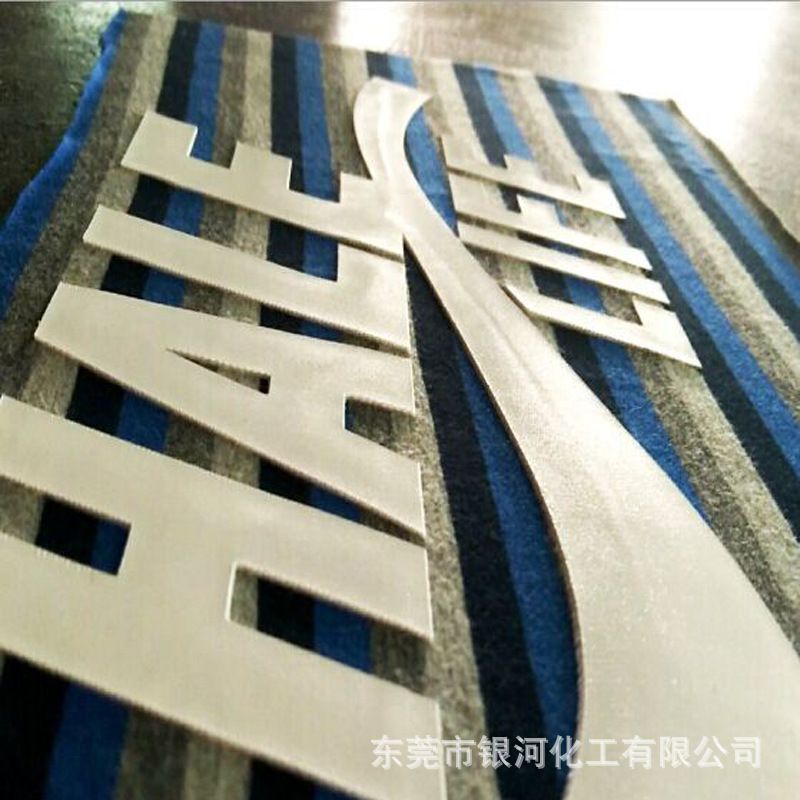

This product is specially designed for the soft hand 3D printing effect required by the market. It adopts the super soft hand rectangular thick plate printing glue developed from foreign imported materials, which solves the problems of hard hand, thick stack and too many printing times.

1,Performance: Performance

Appearance: h-105fm-5 is white, h-105am-5 is pure white;

1. Viscosity: 145000 ~ 150000 CPS;

2. Ionic: non-ionic;

3. Storage period: 8 months (normal temperature, sealed).

2、 Application: apply

1. This product is mainly used for three-dimensional thick plate printing of cotton cloth, such as toys, clothing, webbing, etc. it has the advantages of super soft hand feel, super fast thickening, flat surface without depression, and good printability.

2. This product generally uses 80 mesh 120 mesh screen;

3. The product is not easy to plug the net. When it is too thick, it can be evenly diluted by adding a proper amount of water slurry;

4. In order to ensure the printing effect, it is generally required to print 4-6 times according to different thickness;

5. This product is easy to operate. After the first printing, it needs to be dried completely before the second printing;

6. After natural air drying for 72 hours, over temperature 130-140 ℃ / 15-30 seconds, over temperature the fabric as far as possible;

7. In order to improve the fastness, 1% crosslinking agent can be added.