Products

- Printing ink for High Density series-Hand printing

- Printing ink for High Density series-Machine printing

- Printing ink for machine printing series

- Water-based printing ink

- Printing Material Auxiliaries series

- Printing ink for hand printing

- Dipping material for rope end webbing

Service hotline:

13827210351

current location:Home>>Products > Printing ink for High Density series-Machine printing > text

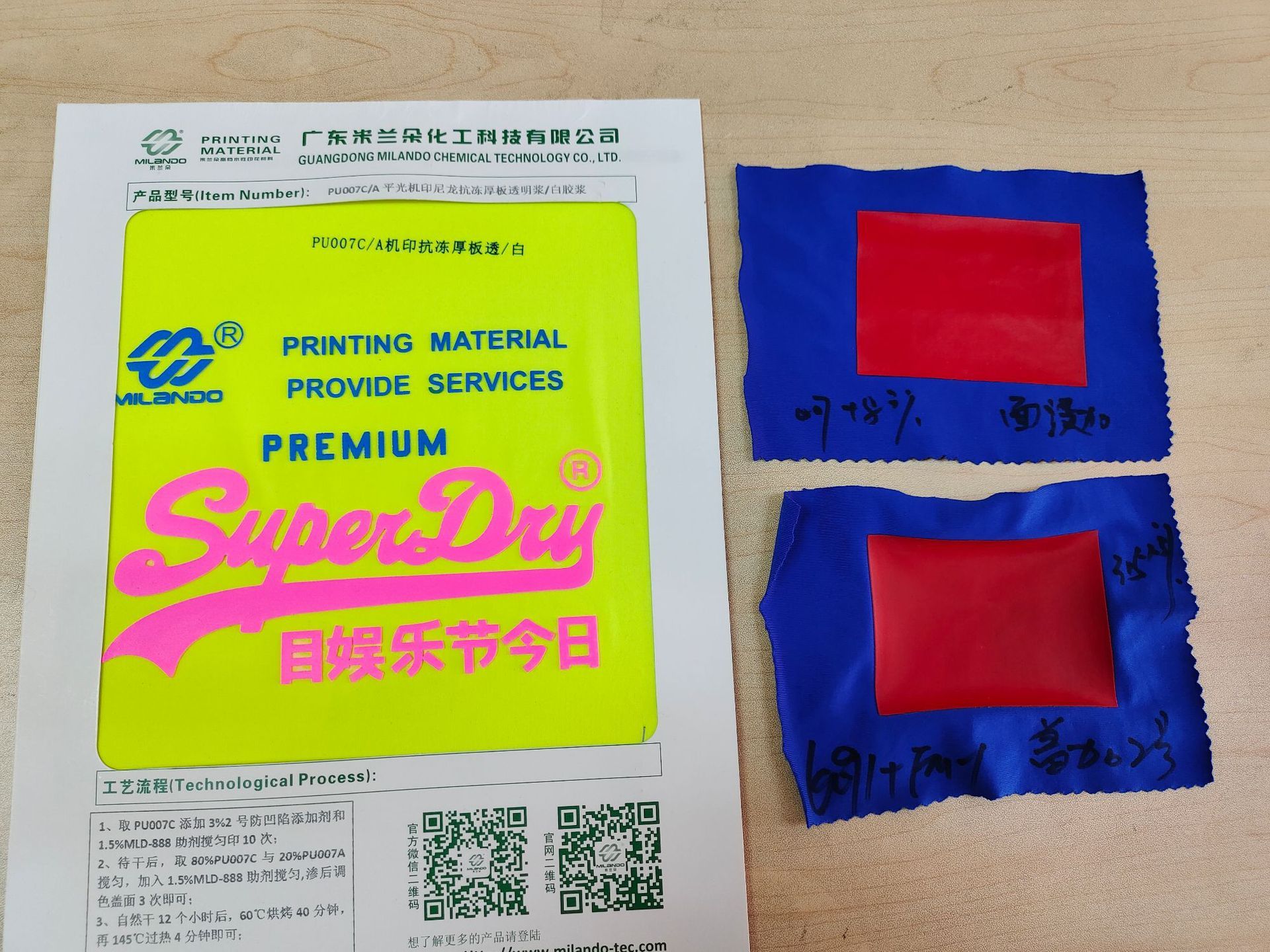

PU007A/C Low-temperature resistant high-density printing ink for nylon fabrics

Product Name: PU007A/C Low-temperature resistant high-density printing ink for nylon fabrics

Brand: MILANDO

Function: High density printing ink for machine printing

Special service: free sample sending

Packing net weight: 5kg

Shelf life: 6 months

By solvent type: water based paint

PU007A/C Low-temperature resistant high-density printing ink for nylon fabrics

Content introduction

PU007A Low-temperature resistant high-density printing ink for nylon fabrics (transparent)

Appearance: PU007C is slightly yellowish, PU007A is pure white

Features: Good thickness, easy to operate, resistance to yellowing, soft feel, dry surface without resticking, smooth effect, low temperature -25℃ frost resistance, it is recommended to reverse overheating treatment after printing drying.

1, viscosity: 12500~13000cps; 2, ionic: non-ionic;

3, storage period: half a year (room temperature, sealed).

Apply

1, This product is mainly used for high-grade nylon cloth, milk silk, swimsuit cloth, sportswear, polyester cloth, knitted cotton cloth, cotton spandex fabric;

2, this product generally uses 80 mesh 120 mesh screen, according to the pattern of the different screen must be taut, this is quite key;

3, this product is not easy to plug the net, too thick can be added to the appropriate amount of water slurry mixing evenly for dilution;

4, in order to ensure the printing effect, generally according to the thickness of the different need to print 8-10 times;

5, 2% of MLD-888 special crosslinking agent must be added when using. It is recommended to use flat screen (ordinary screen version) directly, without making thick version; In the use of thick screen printing, printing after the first need to dry after the second printing;

6, after printing, natural drying for 24-48 hours, or low temperature 60℃-80℃ drying for 45 minutes, and then overtemperature the reverse side of the fabric 135℃ -140℃ for 1-2 minutes (the specific temperature can be adjusted according to the temperature resistance of the fabric).

7, wash water: 60℃ for 90 minutes each time, wash 3 times.

8, Suitable for: hand printing, elliptical printing machine printing, running table printing machine printing, etc.