Products

- Printing ink for High Density series-Hand printing

- Printing ink for High Density series-Machine printing

- Printing ink for machine printing series

- Water-based printing ink

- Printing Material Auxiliaries series

- Printing ink for hand printing

- Dipping material for rope end webbing

Service hotline:

13827210351

current location:Home>>Products > Printing ink for High Density series-Machine printing > text

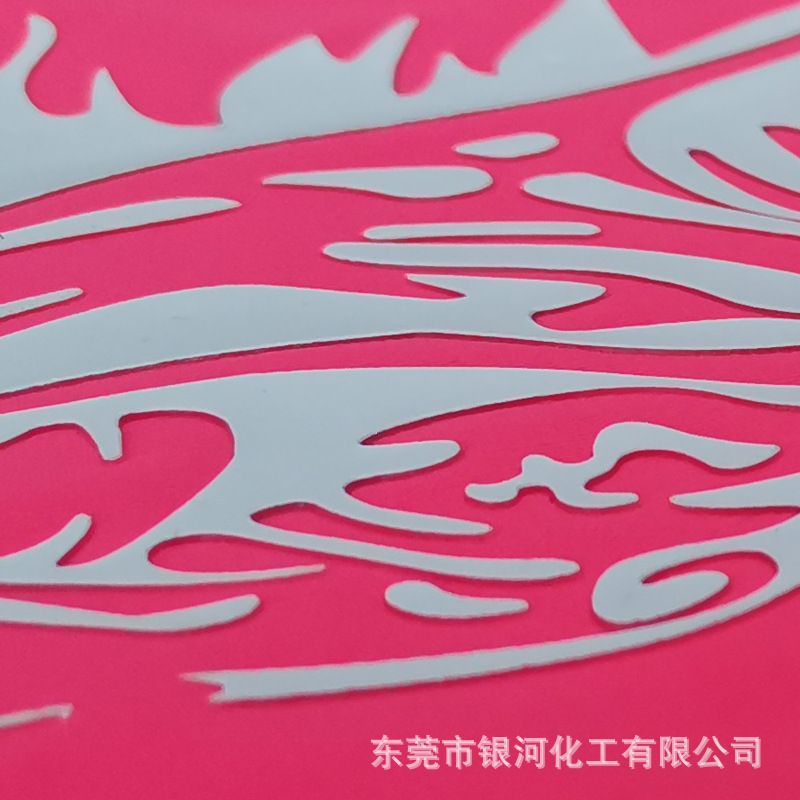

PU008A/C low-temperature resistant HD printing ink for high elastic rubber bands

Product name: PU008A/C low-temperature resistant HD printing ink for high elastic rubber bands

Brand: milando

Function:HD printing ink

Special service: send samples for free

Unit price net weight: 5kg

Shelf life: 6 months

By solvent type: water-based paint

PU008A/C low-temperature resistant HD printing ink for high elastic rubber bands

Content introduction

PU008A low-temperature resistant HD printing ink for high elastic rubber bands(white)

PU008C low-temperature resistant HD printing ink for high elastic rubber bands (transparent)

performance: performance

1,Appearance: PU008C is microemulsion transparent paste, PU008A is white paste;

2,ingredients: imported PU resin, titanium dioxide, additives;

3, storage period: 6 months (room temperature, sealed).

Character: Character

1, super transparent, fast thickness, surface does not stick back, easy to adjust color;

2,Smooth surface, good fastness, elastic tension.

3, Excellent freezing resistance (-20℃ freezing resistance for a week)

4, yellowing resistance (80℃ constant temperature for a week without yellowing)

Apply

1, applicable fabric: high tensile swimsuit, high tensile webbed, thread rack cloth

2, suitable printing method: manual printing or elliptical machine printing;

3, plate requirements: it is generally recommended to use 80-120 mesh screen, while pulling 45 degrees oblique net; The tension is between 15 and 20 Newtons. The distance between the two sides of the pattern and the inner frame is 8-10CM, and the distance between the upper and lower sides is 10-15CM. It is generally recommended to make it into an ordinary plate.

4, operation requirements: A handprint: in the mesh frame around the screw cushion 0.5-0.8CM; Print 6-8 times with PU008, dry each time before printing. Add 2%MLD-888 when using. Surface color mixing cover surface generally add 5-10%PU008A, can adjust the proportion of PU008A according to the color shade; The proportion of color paste is controlled within 8%. Cover with PU008A directly 2-3 times when white.

5, after printing, natural drying for 24-48 hours, or low temperature 60℃-80℃ drying for 45 minutes, and then overtemperature the reverse side of the fabric 130°-140 ° C, 2-3 minutes (the specific temperature can be adjusted according to the temperature resistance of the fabric).